Pneumatic Hoses are the quiet MVPs behind tools, machines, and automation, pumping compressed air to keep industries humming. But here’s the catch – not all hoses are cut from the same cloth. The material you pick can make or break your system’s efficiency, lifespan, and safety. Let’s dive into the showdown between polyamide and plastic Pneumatic Hoses, unpacking what they bring to the table and where they shine.

Why Pneumatic Hoses Love Polyamide: The Lightweight Powerhouses

- Featherweight Champs: Polyamide Pneumatic Hoses are light as a breeze, making them a cinch to handle and fit into tight spots. Less strain, quicker jobs – your crew will thank you.

- Temp Titans: From icy chills to blazing heat, these hoses shrug it off. Perfect for outdoor gigs or places where the thermostat’s always flipping.

- Chemical Ninjas: Oils, solvents, harsh stuff – polyamide Pneumatic Hoses laugh in their face, staying tough in gritty industrial scenes.

- Scuff-Proof: Rubbing against rough edges? No problem. These hoses are built to take a beating and keep on going.

How Pneumatic Hoses Rock Plastic: The Versatile Workhorses

- Wallet-Friendly: Plastic Pneumatic Hoses won’t break the bank, making them a smart pick for tight budgets.

- Bend It Like a Pro: Super flexible, these hoses twist and turn without kinking – a dream for jobs needing constant motion or sharp curves.

- Sun-Proof: Many plastic Pneumatic Hoses scoff at UV rays, holding strong under the sun without cracking. Outdoor life? They’ve got it covered.

- Size Smorgasbord: From tiny to hefty, these hoses come in every shape and fit, so you’ll always find the right one.

Picking the Perfect Hoses: What’s Your Match?

Choosing between polyamide and plastic Pneumatic Hoses boils down to your setup:

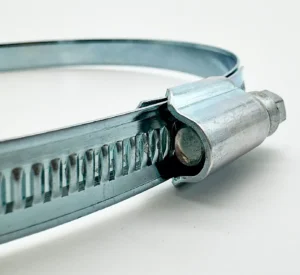

- Pressure Check: Make sure your hose can handle your system’s max push.

- Hot or Cold: Think about the temp swings your Pneumatic Hoses will face.

- Chemical Clash: Got oils or solvents? Pick a hose that won’t blink.

- Flex Factor: Need it to dance around corners? Go for bendy.

- Cash Call: Weigh your budget – quality doesn’t always mean pricey.

Our Premium Hoses: Your Next Upgrade

Ready to juice up your pneumatic game? Our lineup of polyamide and plastic Pneumatic Hoses has you covered. Our pros are on deck to match you with the perfect hose – think top performance, long life, and zero worries.

Don’t roll with hoses that leak, kink, or quit. Bet on quality, bet on reliability, bet on our premium Pneumatic Hoses. Hit us up today for tailored tips and expert vibes. Your system’s ready to roar!