In the realm of industrial infrastructure, the significance of efficient piping systems cannot be overstated. Among the array of solutions available, telescopic pipes with clamps emerge as a versatile and indispensable component. In this detailed guide, we delve into the intricacies of telescopic pipes, exploring their benefits, applications, and key considerations.

Understanding Telescopic Pipes:

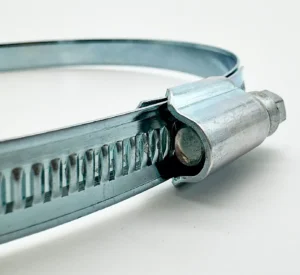

Telescopic pipes, also known as telescoping tubes, are ingeniously designed to offer adjustable lengths, providing flexibility and adaptability in various piping applications. Equipped with clamps for secure attachment, these pipes facilitate easy installation and maintenance, making them a preferred choice across industries.

Benefits:

Customizable Lengths: Telescopic pipes offer adjustable lengths, allowing for precise fitting and alignment in diverse piping systems.

Space Optimization: With their telescoping design, these pipes minimize the need for excess piping material, optimizing space utilization and reducing wastage.

Versatile Applications: From HVAC systems to industrial ductwork, these pipes find applications in a wide range of industries, offering versatility and reliability.

Cost-Efficiency: By eliminating the need for custom-sized pipes and reducing installation time, these pipes contribute to cost savings in both material and labor expenses.

Applications:

Telescopic pipes cater to a myriad of applications across various industries:

HVAC Systems: Facilitate efficient airflow management and temperature control.

Industrial Piping: Enable seamless transportation of liquids, gases, and solids within manufacturing facilities.

Construction Projects: Provide structural support and conduit for electrical wiring and plumbing systems.

Ventilation Systems: Ensure proper air circulation and exhaust in commercial and residential buildings.

Key Considerations:

Material Composition: Opt for high-quality materials such as galvanized steel or stainless steel for durability and corrosion resistance.

Size and Diameter: Consider the specific requirements of your project and select telescopic pipes with suitable diameter ranges to ensure proper fit and functionality.

Clamp Mechanism: Evaluate the design and strength of the clamps to ensure secure attachment and leak-proof connections.

Sheet Thickness: Pay attention to the sheet thickness of the pipes to ensure structural integrity and longevity in demanding environments.

Conclusion:

Telescopic pipes with clamps embody innovation and efficiency in the realm of piping solutions. With their adjustable lengths, versatile applications, and cost-effective benefits, these pipes empower industries to optimize their infrastructure and maximize operational efficiency. Whether you’re embarking on a new construction project or upgrading existing piping systems, these pipes offer a reliable and adaptable solution to meet your needs.

Explore our telescopic pipes with clamps and elevate your piping system to new heights of performance. Contact us today to learn more and embark on your journey towards enhanced industrial infrastructure.