Welcome to our comprehensive guide on hand operated valves. In this guide, we’ll delve into the world of hand-operated valves, focusing specifically on those with and without seals. Whether you’re a professional plumber, an industrial engineer, or a DIY enthusiast, this guide will equip you with the knowledge you need to make informed decisions about your piping system. Let’s get started!

Understanding Hand-Operated Valves:

Hand-operated valves are indispensable components in piping systems, allowing users to manually control the flow of liquids or gases. These valves come in various types and configurations, each serving specific purposes depending on the application and environment.

Valves with Seals:

Valves with seals, also known as globe valves, feature a mechanism that utilizes a sealing element to control flow. The sealing element, typically made of materials like rubber or PTFE, ensures a tight seal when the valve is closed, preventing leakage. Here’s a step-by-step guide on how to use and maintain valves with seals:

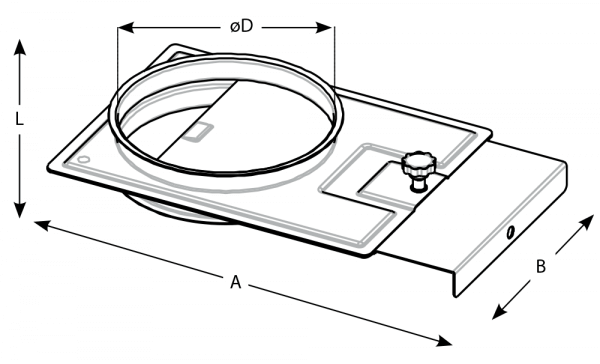

Installation: Begin by selecting the appropriate valve size and material based on your application requirements. Ensure that the valve is installed correctly according to the manufacturer’s guidelines, with proper alignment and tight connections.

Operation: To operate a valve with a seal, simply turn the handwheel or handle in the desired direction to open or close the valve. Exercise caution not to exert excessive force, as it may damage the sealing element or the valve mechanism.

Maintenance: Regular maintenance is essential to ensure optimal performance and longevity of valves with seals. Inspect the sealing element periodically for signs of wear, tear, or damage, and replace it if necessary. Lubricate the valve mechanism as recommended by the manufacturer to prevent friction and ensure smooth operation.

Valves Without Seals:

Contrary to valves with seals, valves without seals, such as ball valves or butterfly valves, operate without a traditional sealing element. Instead, they rely on the precise alignment of internal components to control flow. Here’s a comprehensive guide on using and maintaining valves without seals:

Installation: Similar to valves with seals, proper installation is critical for valves without seals. Ensure correct alignment and tight connections to prevent leakage and ensure optimal performance.

Operation: Operating a valve without a seal is straightforward. Turn the handle or lever to open or close the valve, allowing fluid or gas to flow through the pipeline. Exercise caution to avoid applying excessive force, which may damage the valve components.

Maintenance: While valves without seals may require less maintenance compared to their sealed counterparts, periodic inspection is still necessary. Check for any signs of corrosion, erosion, or leakage, and address any issues promptly to prevent further damage.

Types of Hand Operated Valves:

In addition to globe valves and ball valves, there are several other types of hand-operated valves commonly used in piping systems. Here are a few examples:

Gate Valves: Gate valves are designed to control the flow of fluids by raising or lowering a gate mechanism. They are often used in applications where a straight-line flow of fluid with minimal restriction is required.

Check Valves: Check valves, also known as non-return valves, allow fluid to flow in only one direction. They automatically prevent backflow, making them essential for applications where reverse flow is undesirable.

Needle Valves: Needle valves feature a slender, tapered needle-like plunger that precisely regulates the flow of fluids. They are commonly used in applications requiring fine flow control, such as instrumentation systems.

Butterfly Valves: Butterfly valves control flow using a circular disc or vane positioned at right angles to the flow. They offer quick and easy operation, making them suitable for large-volume applications.

Conclusion:

Hand-operated valves play a crucial role in controlling the flow of fluids and gases within piping systems. Whether you opt for valves with seals for enhanced sealing capabilities or valves without seals for simplicity and reliability, proper installation, operation, and maintenance are key to ensuring optimal performance and longevity. We hope this guide has provided valuable insights into the world of hand-operated valves. For a wide selection of high-quality valves and piping accessories, check out our products.