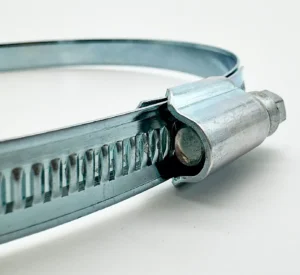

In the realm of construction, plumbing, and various industrial applications, the threaded sleeves play a pivotal role in securing and strengthening connections. These small yet crucial components offer versatility, reliability, and ease of installation, making them indispensable in a wide range of projects. In this detailed guide, we explore the intricacies of these sleeves, their types, applications, and key considerations.

Understanding Threaded Sleeves:

Threaded sleeves, also known as coupling nuts or threaded inserts, are cylindrical metal components with internal threading designed to join two objects or components together. They provide a secure and durable connection by creating a threaded interface for screws, bolts, or studs. Those sleeves come in various materials, sizes, and configurations to accommodate different applications and requirements.

Types of Threaded Sleeves:

Straight Sleeves: These sleeves feature straight internal threading throughout the entire length, providing a uniform interface for fasteners.

Reducing Sleeves: Designed to connect objects with different thread sizes, reducing sleeves feature internal threading of varying diameters to accommodate different fastener sizes.

Flanged Sleeves: Flanged sleeves include a flange at one end, providing additional support and stability when installed.

Knurled Sleeves: Knurled sleeves feature a textured surface or knurled pattern, offering improved grip and torque resistance during installation.

Applications :

Threaded sleeves find applications in various industries and projects, including:

Construction: Strengthening structural connections and assemblies in buildings, bridges, and infrastructure projects.

Plumbing: Joining pipes and fittings in plumbing systems for leak-proof connections.

Automotive: Securing components and parts in vehicle manufacturing and repair.

Machinery: Fastening parts and components in machinery and equipment assemblies.

DIY Projects: Enhancing home improvement projects with secure and reliable connections.

Key Considerations :

Material: Consider the environmental conditions, load requirements, and corrosion resistance when selecting the material for threaded sleeves. Common materials include stainless steel, brass, and aluminum.

Size and Configuration: Ensure compatibility with the fasteners and components being joined by selecting these sleeves with appropriate sizes and configurations.

Installation Method: Evaluate the installation method and tools required for threaded sleeves, ensuring compatibility with the project requirements and available resources.

Load Capacity: Consider the load-bearing capacity and strength requirements of the these sleeves to ensure reliable performance in the intended application.

Conclusion:

Threaded sleeves are versatile and indispensable components in various industries and projects, providing secure and durable connections for a wide range of applications. Whether you’re constructing a building or plumbing a system, threaded sleeves offer a reliable solution for strengthening connections and enhancing project efficiency.

Explore our own sleeves and elevate your projects with secure and reliable connections.