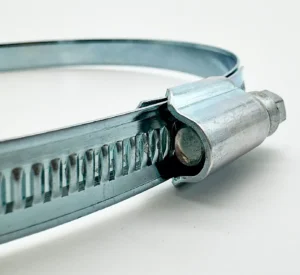

Are your hoses leaking, popping off, or just not performing as they should? The culprit might be your hose coupling. These unsung heroes of fluid transfer are essential for everything from gardening to industrial manufacturing. But with so many types, sizes, and configurations to choose from, finding the perfect match can feel overwhelming. Fear not! This masterclass will equip you with the knowledge you need to connect, seal, and succeed with hose couplings.

The Anatomy of a Hose Coupling: Decoding the Parts

Let’s start by getting familiar with the key components of a hose coupling. Every coupling consists of a body, a tail (optional), and a locking mechanism. The body is the main part that connects to the hose, while the tail (if present) provides additional support and helps prevent kinks. The locking mechanism secures the connection, ensuring a tight seal and preventing leaks.

Different types of couplings use different locking mechanisms. Common options include threaded connections, cam and groove couplings, and quick-release couplings. The right choice for you depends on your specific needs and application.

Couplings also come in various materials, including brass, stainless steel, and plastic. Each material has its own advantages and disadvantages in terms of durability, corrosion resistance, and chemical compatibility. Additionally, couplings are available in a wide range of DN sizes, which indicate the internal diameter of the hose they are designed to fit.

Beyond the Basics: Specialized Couplings for Unique Needs

While standard couplings are suitable for many applications, there are also specialized couplings designed to handle specific challenges. For instance, high-pressure couplings are built to withstand extreme pressures, while high-temperature couplings are made from materials that can resist heat degradation. If you’re working with corrosive fluids, chemical-resistant couplings are essential to prevent leaks and damage.

Choosing the right specialized coupling can significantly improve the safety, efficiency, and longevity of your hose system. It’s worth investing in high-quality couplings that are specifically designed for your unique needs.

DIY Coupling Hacks: Tips and Tricks for the Home Mechanic

Even if you’re not a professional plumber, you can still master the art of hose coupling. Here are a few tips to get you started:

Choose the right size: Make sure your coupling matches the inner diameter of your hose.

Inspect before connecting: Check for any damage or debris that could compromise the seal.

Hand-tighten only: Overtightening can damage the coupling or the hose.

Lubricate threads: This will make it easier to connect and disconnect threaded couplings.

Store couplings properly: Keep them clean and dry to prevent corrosion and damage.

Coupling Confusion? Explore Our Range & Get Expert Advice

Still feeling unsure about which coupling is right for you? Don’t worry! Explore our wide selection of hose couplings to see the different options available, and if you need personalized guidance, our team of experts is here to help. We can assess your specific needs and recommend the perfect coupling for your application.