Are you ready to take your pipeworks to the next level? Look no further than segment bends – the unsung heroes of fluid flow redirection. In this comprehensive guide, we’ll delve into everything you need to know about segment bends, from their benefits to applications, and how to choose the perfect one for your project. Let’s dive in!

Understanding Segment Bends: What Are They?

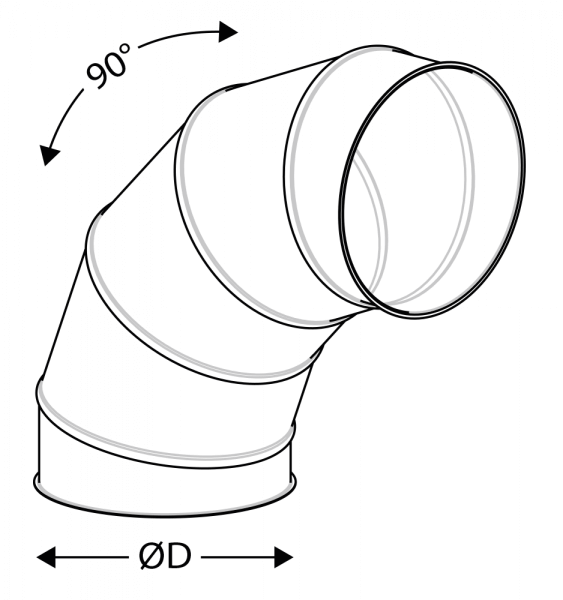

Segmented bends are essential components in plumbing systems, providing precise angles for redirecting fluid flow. Made from durable materials like galvanized steel, these bends ensure stability and reliability, even in demanding environments.

Benefits of Segment Bends: Why Choose Them?

Precision Engineering: Segmented bends are meticulously crafted for accuracy, ensuring seamless flow redirection without leaks or disruptions.

Versatility: With various diameters and thickness options, segment bends cater to a wide range of piping needs, from residential to industrial applications.

Durability: Made from robust materials like galvanized steel, these bends withstand corrosion and environmental factors, ensuring long-term performance.

Ease of Installation: Many segmented bends come with pre-installed flanges, simplifying the installation process and saving valuable time and effort.

Applications of Segmented Bends: Where Can You Use Them?

Segment bends find utility across diverse industries and applications:

Industrial: Factories, warehouses, and manufacturing plants rely on segmented bends for efficient fluid flow management in their piping systems.

Commercial: Offices, hotels, and shopping centers benefit from segmented bends to ensure reliable plumbing solutions.

Residential: From kitchen renovations to bathroom upgrades, segmented bends play a crucial role in maintaining efficient water distribution in homes.

HVAC: These bends are essential components in HVAC systems, facilitating optimal airflow in ductwork and ventilation setups.

Agricultural: Farms and agricultural operations utilize segmented bends for irrigation systems, ensuring efficient water distribution to crops and machinery.

Choosing the Right Segment Bend: Key Considerations

When selecting a segment bend for your project, consider the following factors:

Diameter and Thickness: Choose a bend with the appropriate diameter and thickness to suit your piping requirements.

Material: Opt for high-quality materials like galvanized steel for durability and corrosion resistance.

Flange Options: Determine if you need segment bends with pre-installed flanges for easy installation.

Conclusion:

Segmented bends are indispensable components in plumbing systems, offering precision, durability, and versatility across various industries. Whether you’re embarking on an industrial project or upgrading your home plumbing, segment bends provide reliable solutions for efficient fluid flow redirection. Explore our wide range of segmented bends today and experience the difference in your pipeworks!